Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

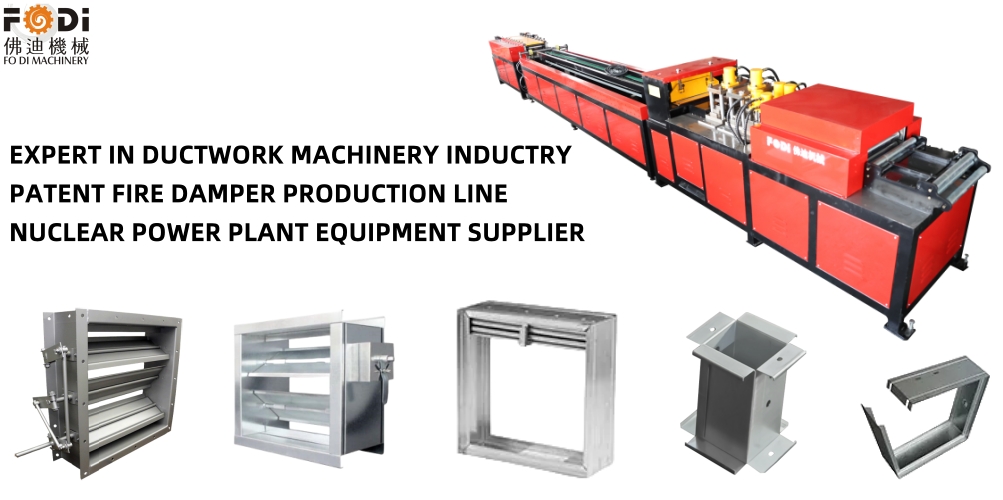

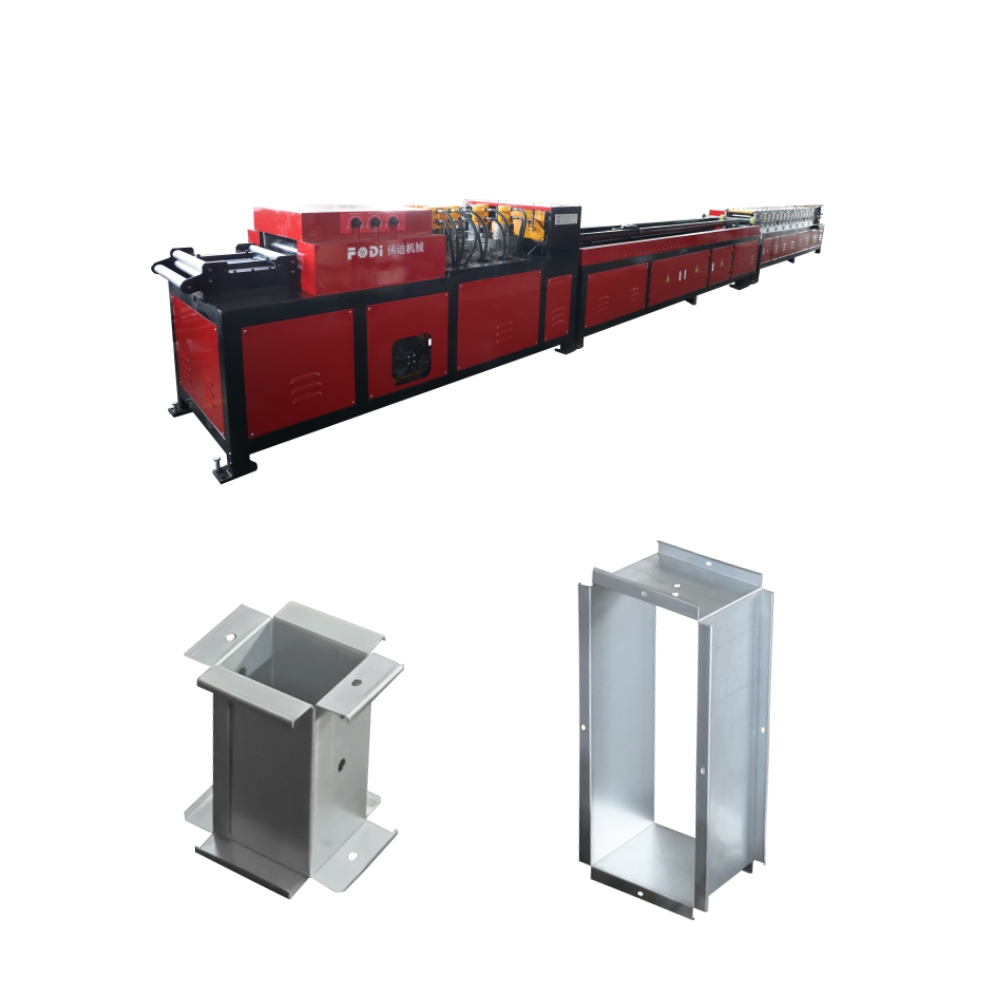

Fire Damper Automatic Production Line

The fire damper series of equipment mainly consists of: (I) the Frame production line; (II) the blade forming machine; (III) the support bar forming machine; (IV) the leaf spring forming machine; (V) the positive pressure air supply outlet production line; (VI) the positive pressure air supply outlet baffler production line; (VII) the riveting platform; and (VIII) the related complementary molds.

Name, model, specification | Remark |

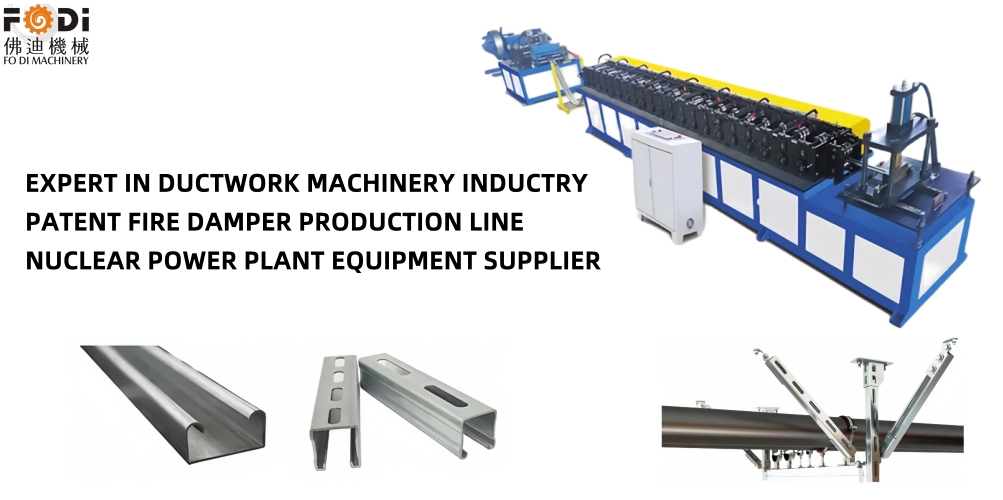

Fully automatic adjustable frame for HAVC/fire damper production line | Common plate flange: 34mm; steel angle flange : 30-40mm; width: 200-320mm |

Fully automatic fixed-width frame for HAVC/fire damper production line | Common plate flange: 34mm; the width and height of the flange is customizable |

(I) Main Features:

1. More speed, and fewer workers. It manufactures 300-400 Fire Damper frame per 8 hours per shift of 1-2 workers.

2. Higher precision. The guaranteed hole centerline error is ±0.3mm, the length error ±0.3mm, and the diagonal error ±1mm.

3. More raw materials saved. The cutting comes before the forming, so that no waste is generated from debugging through production.

4. Higher efficiency. With the continuous PO mode, the data of up to 8 POs can be entered in the system one time, so that products can be manufactured continuously.

5. Better forming result. The rolling wheel, which is specially designed, minimizes any scratch of the galvanized sheet through the forming process.

6. Smaller bending radius. The specially designed bender, and the pre-dented notching area ensures the perpendicular folding operation.

7. Robust system. Main machine parts are precisely calculated, with sufficient design margin, so that the production line can have stable output in an intensive and heavily-loaded environment.

E | Rotor shaft hole |

The Nr.of Rotor shaft hole depends on you | |

F | Fuse hole |

G | Adjustable |

(II) Main Components

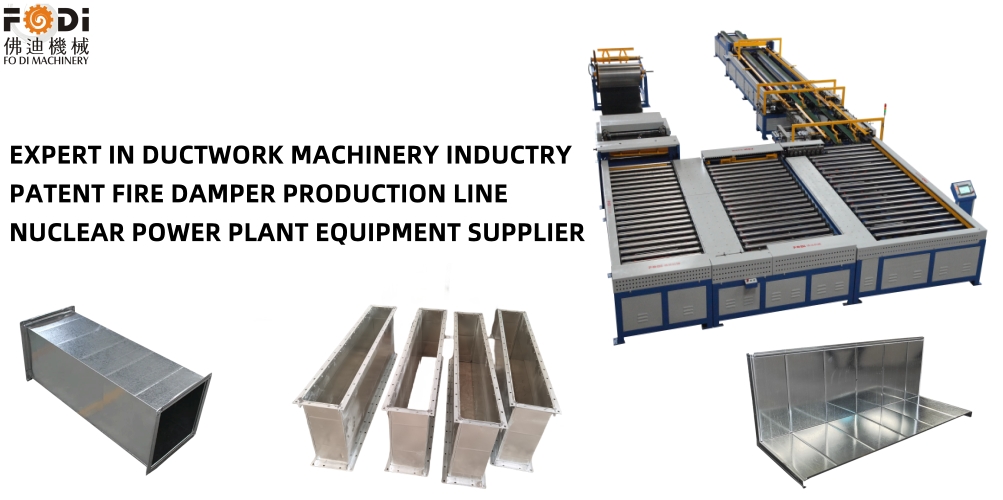

1. One set of 5T non-powered internally-braced feed rack

2. One set of leveling, punching, notching and cutting machine

3. One piece of feeding platform

4. One set of adjustable-width (or fixed-width) Frame forming machine, and one set of hydraulic bending mechanism

5. Two sets of hydraulic system

6. One set of computer control system

(III) Production Flow Processes and Main Features:

Decoiling → Setting sheets to right direction → Leveling → Punching big/small openings → Punching mounting holes → Punching fuse holes → Punching flange holes for common plate or steel angle (optional)→ Hydraulic fixed-length cutting → Feeding over the platform → Forming adjustable-width (or fixed-width) common plate (or steel angle) flange → Automatic hydraulic folding to 90 degrees → Manual discharge

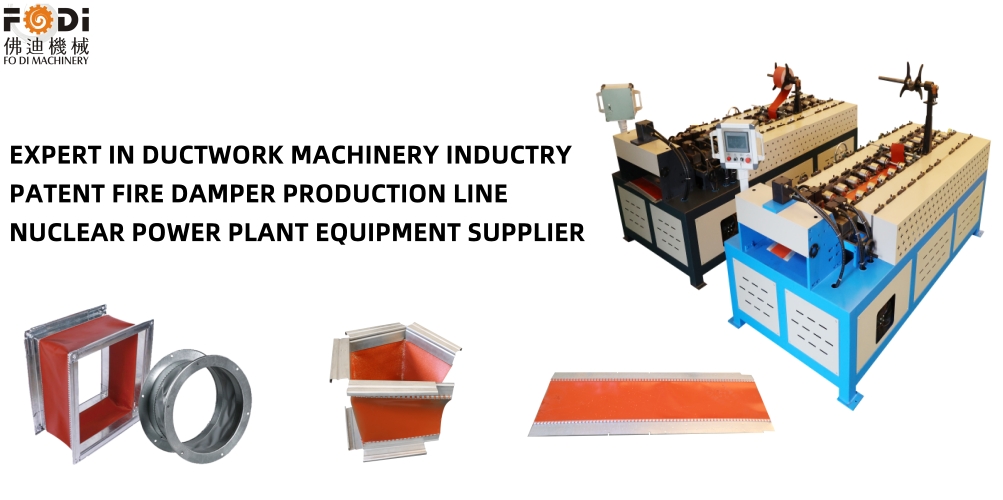

Fire damper other accessories

Fire Damper Blade Making Machine | Fire Damper Spring Leaf Making Machine | Fire Damper Support Bar Making Machine | Fire Damper Rivet Table |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|

|

|

|