Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

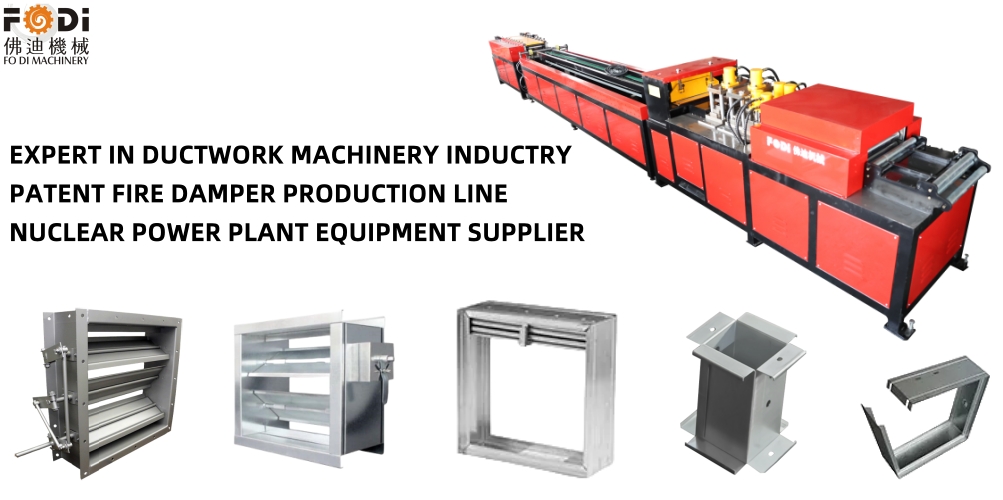

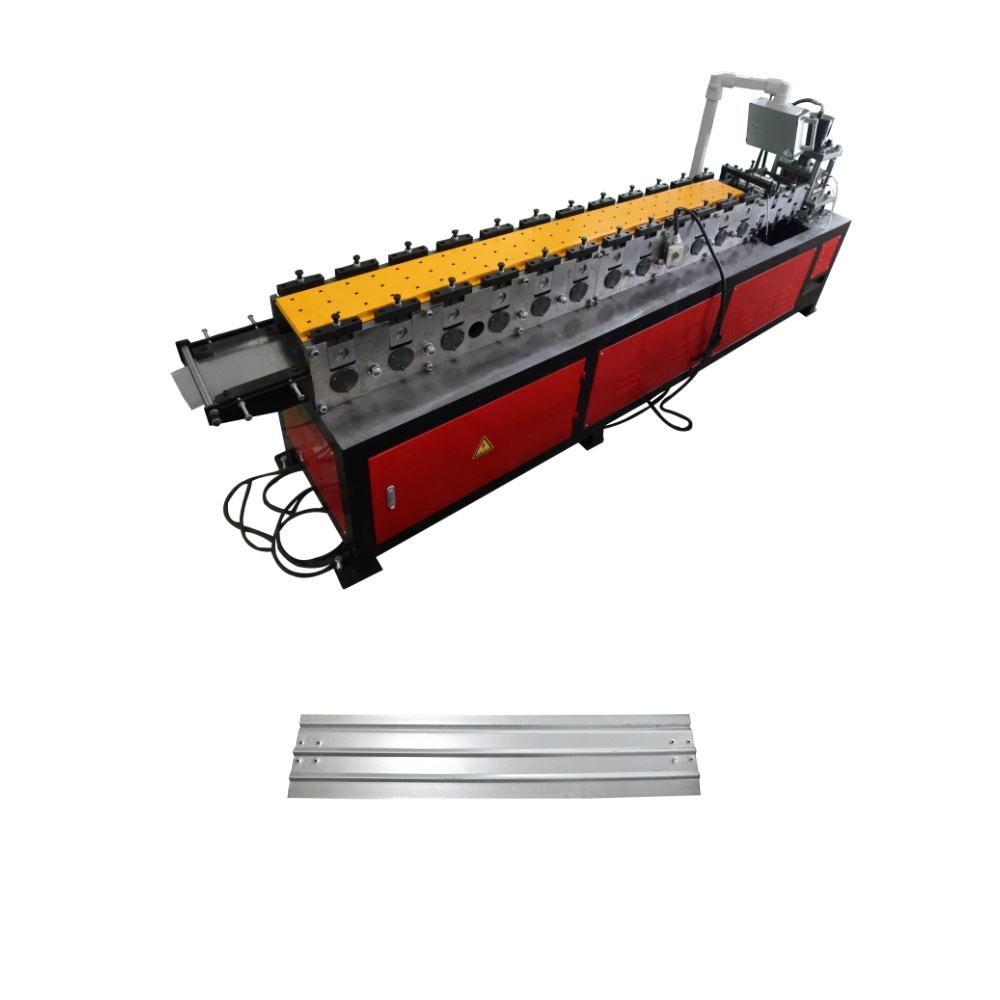

HVAC Damper Blade Roll Forming Machine, Fire damper blade

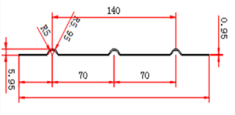

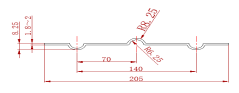

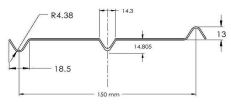

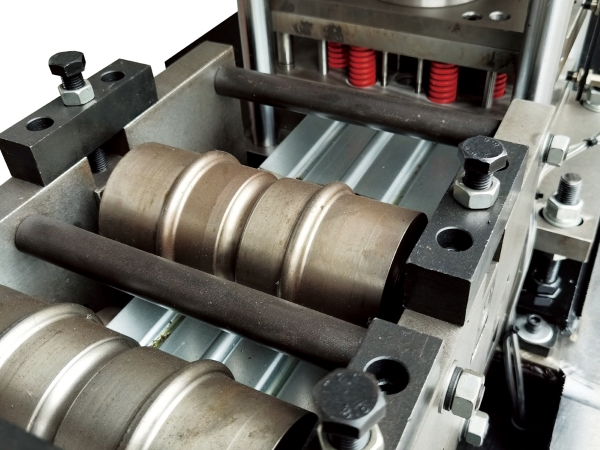

Reference shapes | ||

grooving on same direction | grooving on different direction | grooving on different direction |

|

|

|

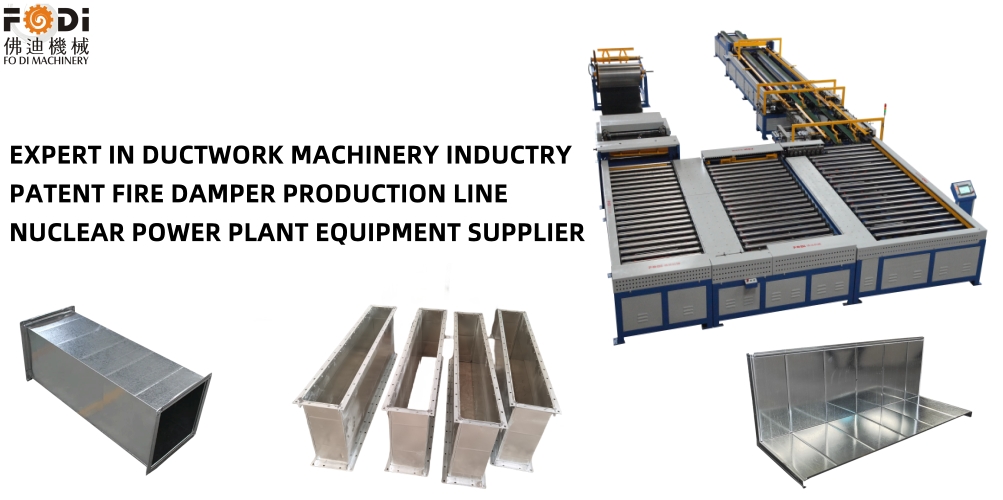

(II) Production Flow Processes and Main Features

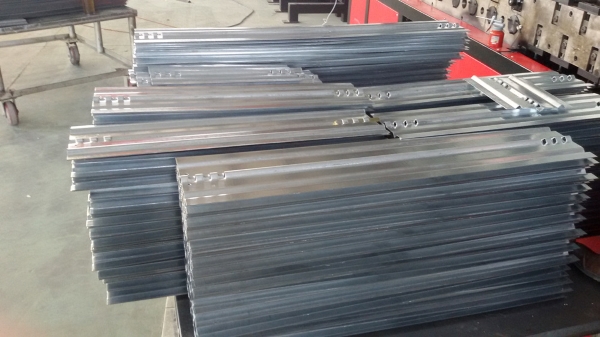

Decoiling → Cold roll forming → Straightening, shaping → Cutting to length, punching → Manual discharge

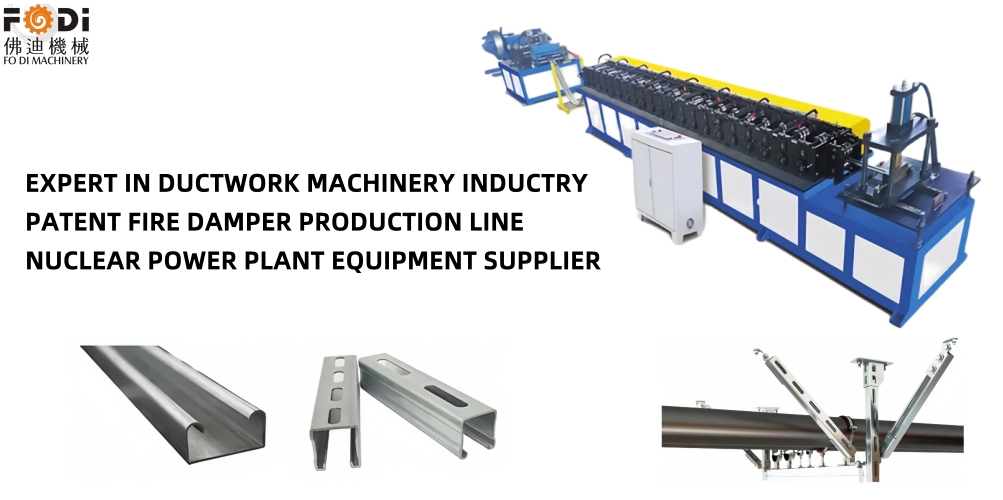

(III) Components List

1. Two non-powered manual internally-braced feed racks

2. One set of main forming machine

3. One set of cutting, punching and notching molds

4. One set of electric control system

5. One set of hydraulic control system

(IV) Main Technical Parameters

1. Material: Galvanized sheets

2. Thickness: 1.5-2.0mm

3. Coil width: 156/166/176/186/196/210mm

4. Coil weight: ≤2000kg

5. Blade size: 150/160/170/180/190/204mm

6. Center-to-center distance between left and right ribs: 102mm (for round ribs)

7. Max width of blade formed: ≤204mm

8. Blade cover plate hole notched or punched: As per the requirement of the customer

9. Motor power: 7.5KW/4KWw

10. Roll Forming Speed: 1-15 meters, adjustable if necessary

11. Blade length error: ±0.5mm/1000mm

12. Blade evenness: ≤1mm/1000mm

13. Control method: PLC

14. Main power supply: 380V 3HP 50HZ

15. Pressure output of hydraulic system: 25MPa, and the working pressure is 8-12MPa

16. Production line size: Approx. 6000mm×700mm×1200mm (L×W×H)

Damper blade forming machine makes manufacture of damper blade easier. With roller stations, it can process material of 1.5-2.0mm thickness. Combine with a decoiler and cutting unit, an auto line can be provided with PLC controlling. We can also manufacture the machine based on the blade profile as customer require. The machine is servo driven and full automatic operation. Circle or square bead are available. The blade can be made with slitting or without slitting. Blade length and number can be customized by set in the CNC controller.

Fire damper other accessories

Fire Damper Rivet Table | Fire Damper Spring Leaf Making Machine | Fire Damper Support Bar Making Machine | Fire Damper Frame Making Machine |

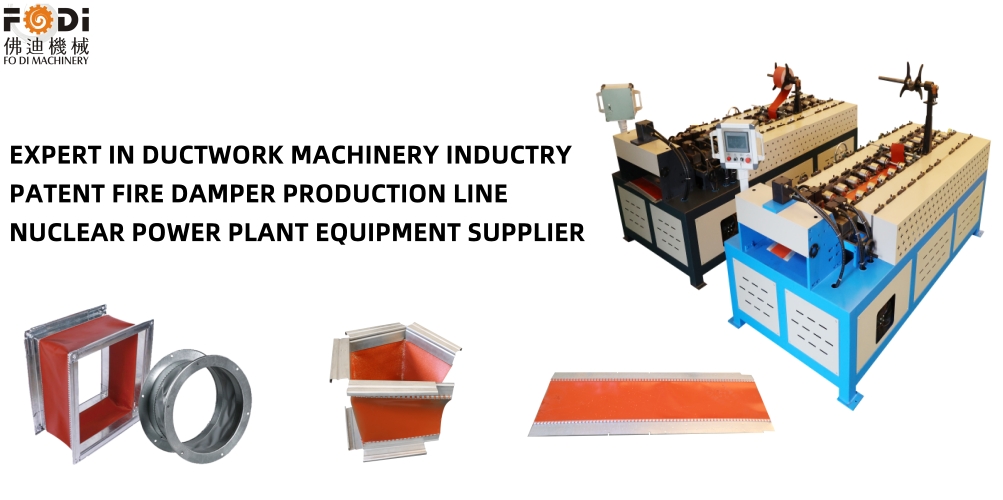

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|

|

|

|