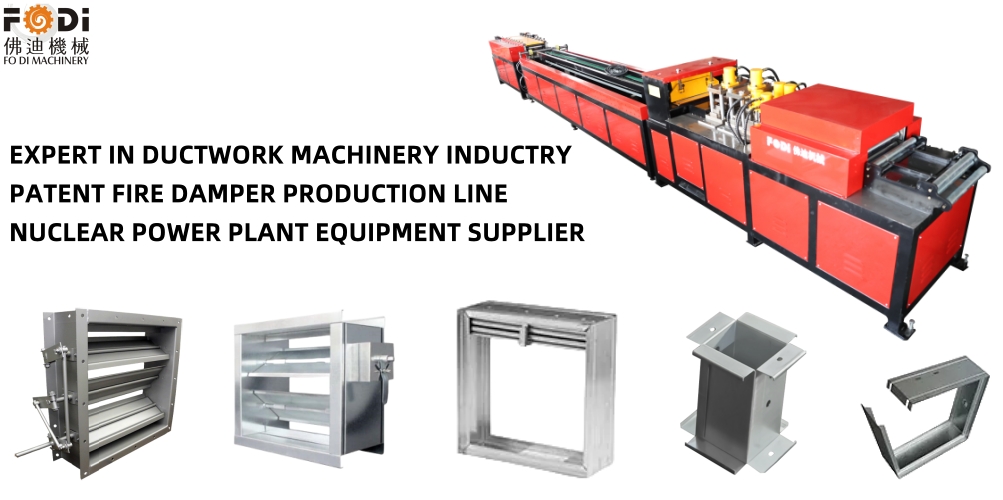

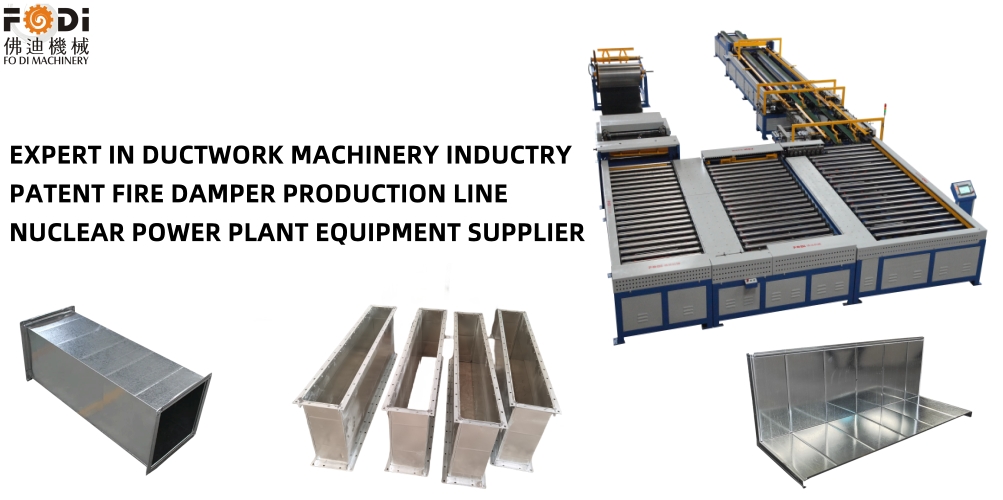

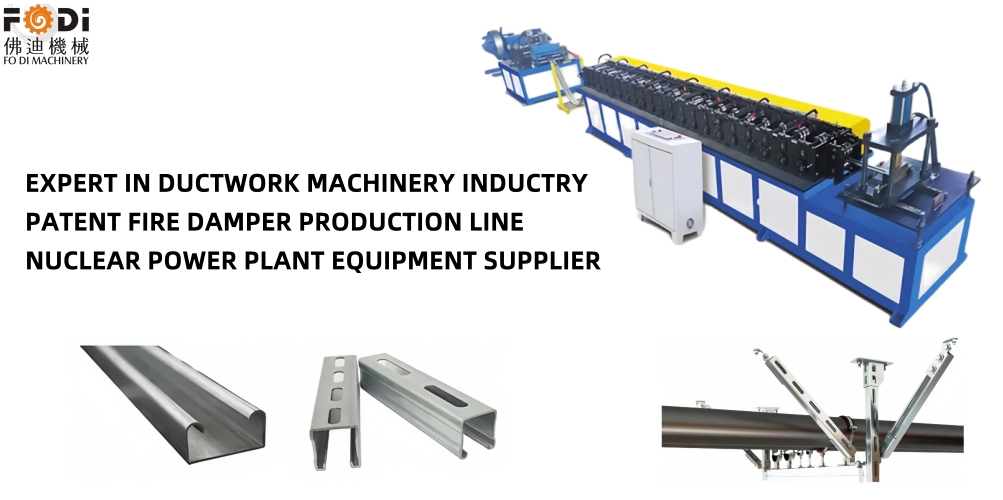

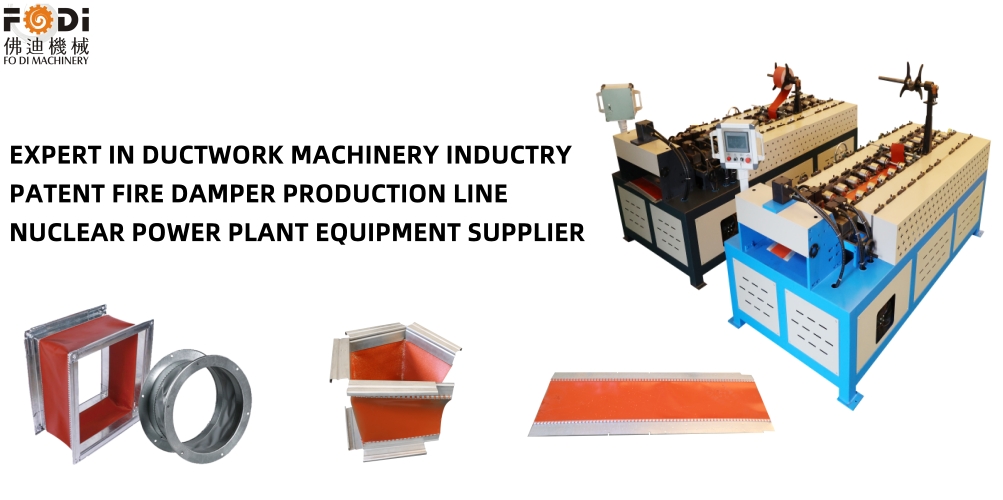

Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

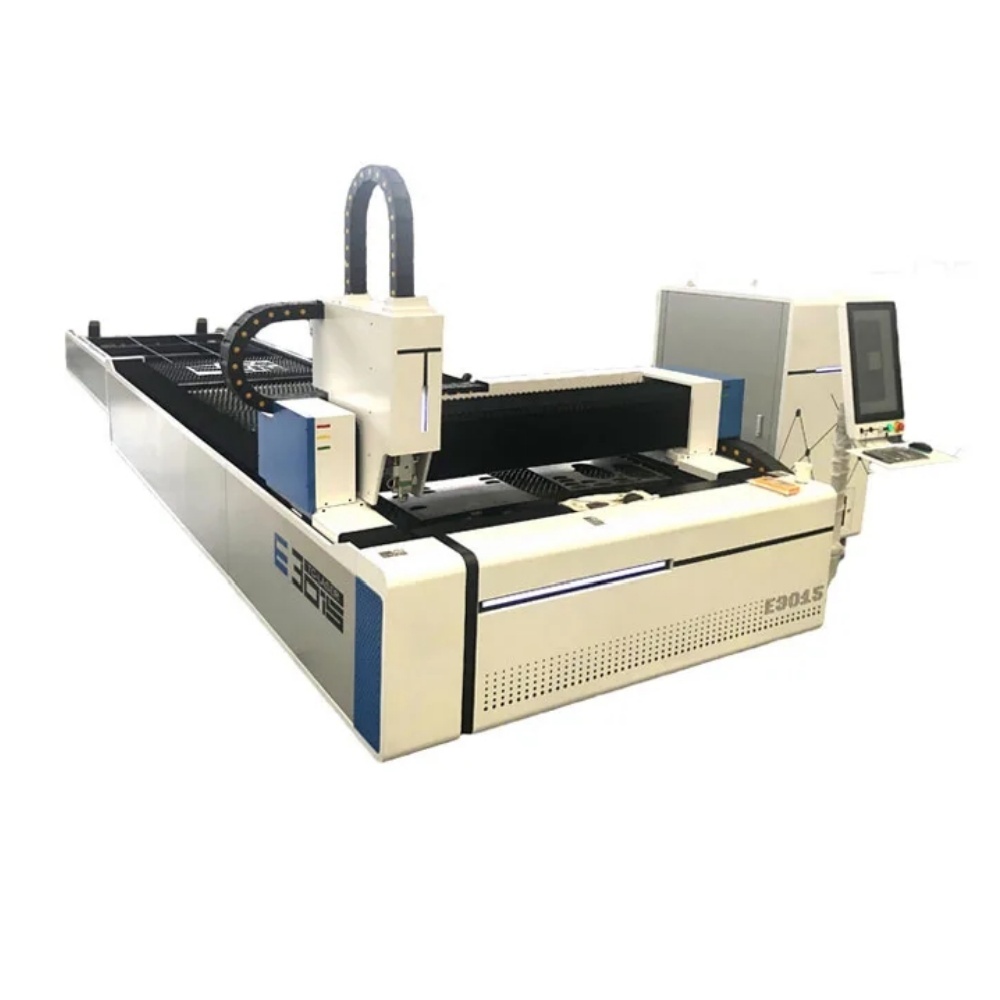

Fiber laser cutting machine

Fiber laser cutting machine is used to cut mild steel,stainless steel, aluminum alloy, brass and other kinds of steel; applicable to sheet metal cutting, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts, arts and crafts, tool processing, advertising, various metal cutting industries.

Introduction and configuration of single platform laser cutting machine

Compared with traditional oxyacetylene, plasma and other cutting processes, fiber laser cutting machine has fast laser cutting speed, narrow slit, small heat-affected zone, good verticality of slit edge, and smooth cutting edge. At the same time, there are many kinds of materials that can be cut by laser. , including carbon steel, stainless steel, alloy steel, aluminum, copper materials, etc.

The core transmission parts of the machine tool, the reducer, gear, and rack are all imported brands, and the core components are selected from well-known brands to ensure that the long-term high-speed cutting accuracy of the equipment remains unchanged and durable.

The control system is simple and visually operated, intuitively adjusting laser power, gas type and pressure; intelligent edge finding, automatic positioning; multi-type file import support, automatic generation, intelligent typesetting, flexible process, image display, and easy operation. The special processing system for laser sheet metal processing is easy to install, easy to operate, excellent in performance, complete in process solutions, realizes stable and high-precision cutting, integrates powerful data process database, and brings simple, convenient and efficient intelligent experience to users.

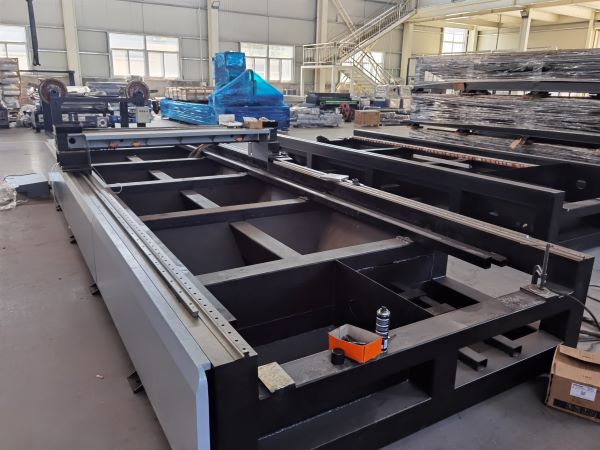

1. The frame as a whole adopts a 150*150 square tube welding structure. After stress-relief annealing, rough and fine machining, secondary aging treatment eliminates stress, prevents deformation, and is more durable. After high-temperature annealing and natural aging, the welding stress is eliminated to ensure long-term use. Deformation, the machine tool has excellent shock resistance and stability, which effectively guarantees high speed, high precision and high stability of the whole machine during high-speed cutting.

2. The beam is welded with marine steel plates, double annealed, and its strength is 1.5 times that of traditional aluminum beams, ensuring reliable and stable high-speed operation.

3.Intelligent dual drive, adopting gantry type imported brand dual servo motor drive system, synchronous dual drive, effectively ensuring high speed, high precision and high stability of the whole machine during cutting.

4. Single-mode CW fiber laser adopts modular design, the system is highly integrated, maintenance-free and highly reliable. The laser power is continuously adjustable, with high beam quality and high laser stability. It is an ideal laser source for laser fine cutting, precision welding and other applications. Using optical fiber with QBH head output, it can cooperate with laser processing head, galvanometer, etc. for system integration with robots, machine tools, etc., and is widely used in 3C, hardware, medical, automotive, aviation and other fields.

5. The BT series is a fiber cutting head suitable for small and medium power launched by Swiss RAYTOOLS AG in 2016. Its diversified interface settings enable it to match with various mainstream fiber lasers. This cutting head adopts an optimized optical design, which is extremely light in weight, small in size and easy to use. It can be used with a height sensor to make cutting more efficient and has a very high cost performance. It is the first choice for small and medium power laser cutting equipment.

Other machines for air duct you may need

Air Duct Corner Assemble Machine | Hydraulic Air Duct Seam Closer | Welding Machine for Angle Steel | TDF Folding Machine |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|