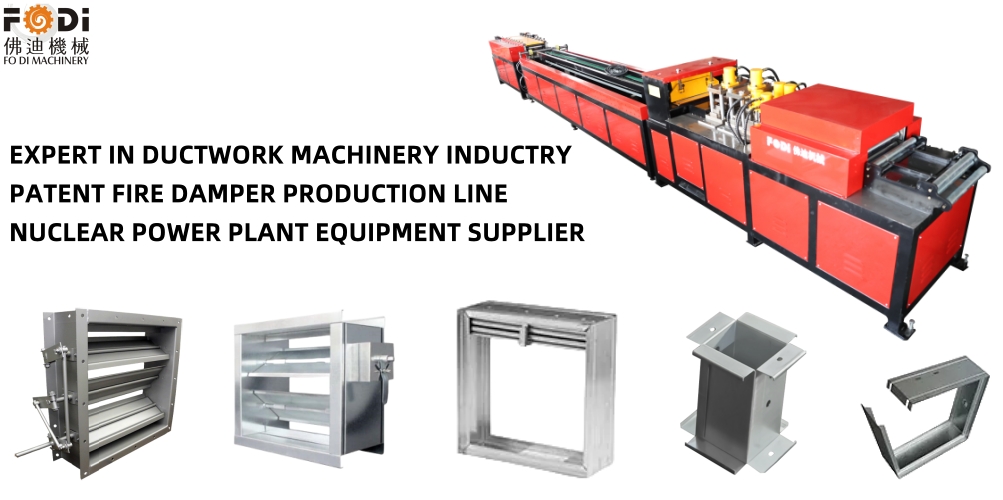

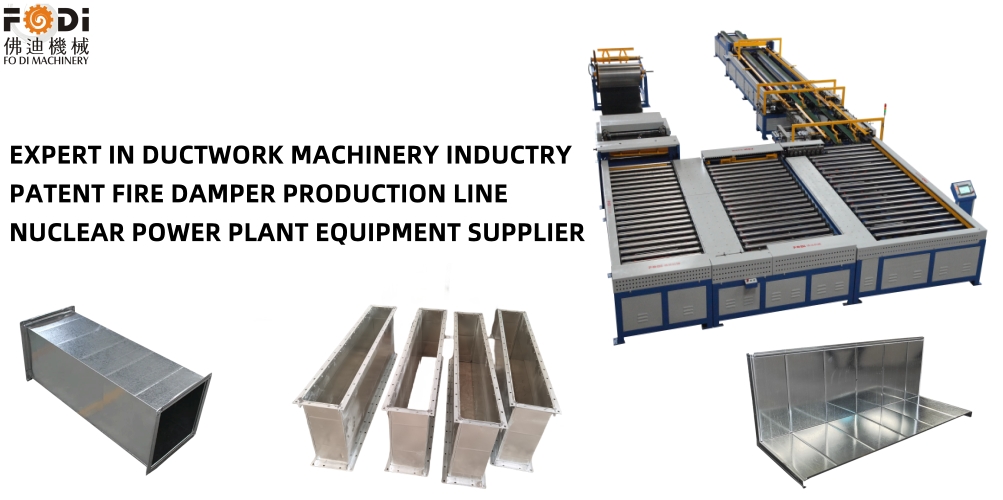

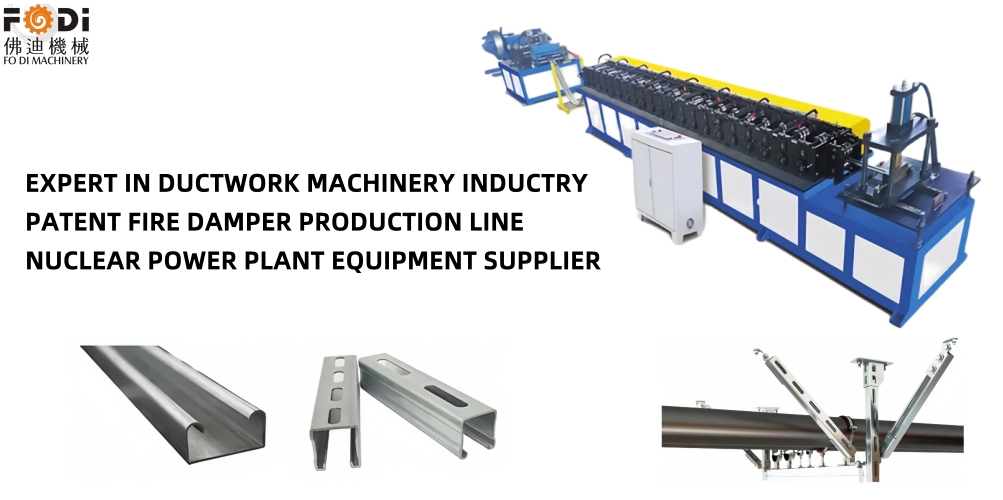

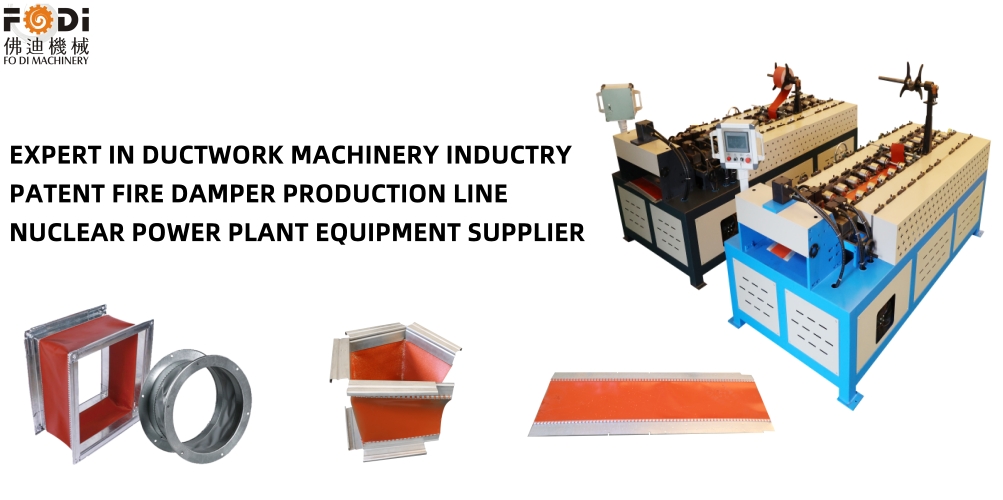

Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

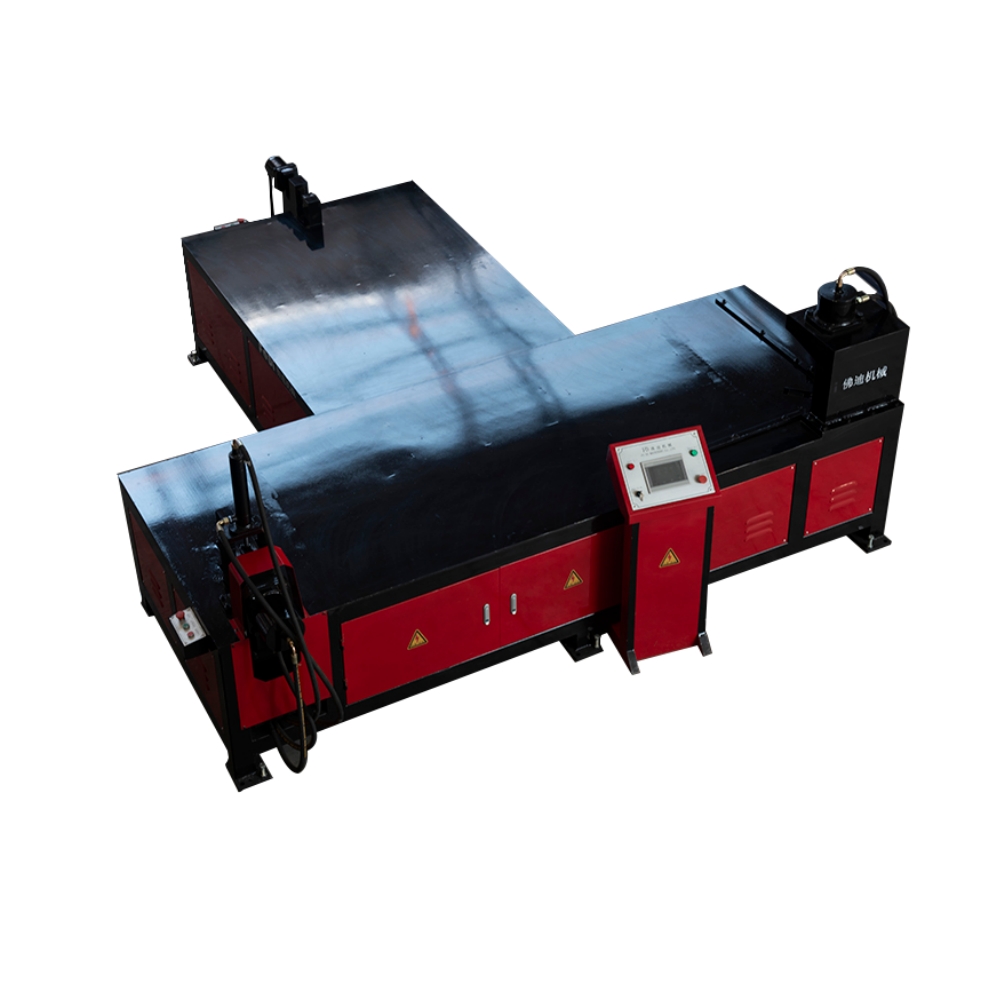

Fire Damper Rivet Table, Fire damper Riveting platform

The damper fastening platform consists of frame riveting (four rivets), corner riveting (four rivets), supporting bar riveting (double rivets) and weather strip riveting (single rivet). Double rivets model and single rivet model can be configured according to customers’ requirements. There are two models can choose. One is rotating wall, the other is rotating bracket. The machine is very easy to operate.

(I) Main Components

1. One set of platform for both corner bracing and Frame riveting (or if so required by the customer, one stand-alone platform for corner bracing, and one for Frame riveting).

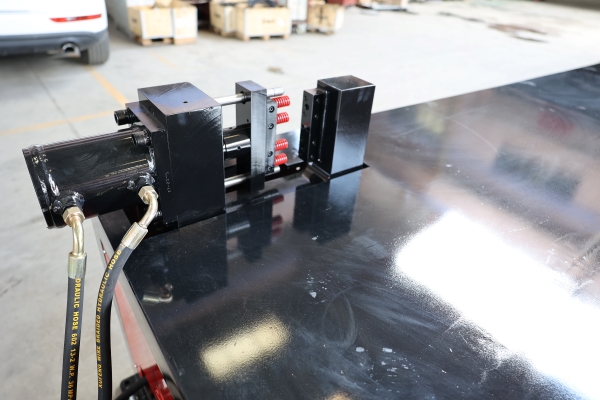

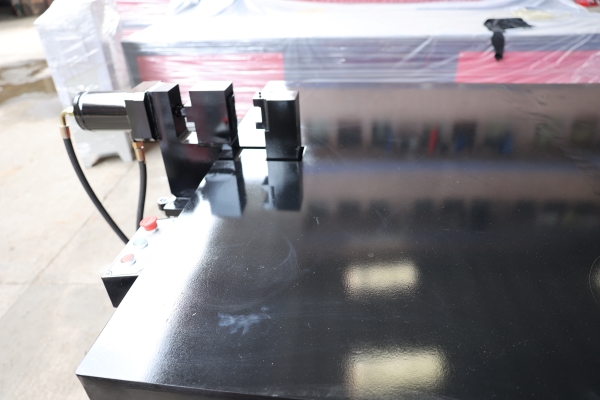

2. One set of support bar riveting platform

3. One set of stand-alone suspension mechanism for weatherstrip riveting

4. Four sets of hydraulic system

5. One computer desk

(II) Production Flow Processes

Fire damper Frame (positive pressure air supply outlet) riveting (at four points simultaneously) → Corner brace riveting (at four points simultaneously) → support bar riveting (at two points simultaneously) → Blade mounting → Weatherstrip riveting (at a single point) → Mechanism installing → Finished valve product

(III) Main Technical Parameters

Riveted valve thickness: 200-320mm

Riveted valve size: Min 180*180mm, or max 3000*3000mm

Riveting material required: 1.2-2.0mm galvanized sheet

Riveting efficiency: 4 sec/time, excluding clamping

Platform size: 3600*3600*850mm (L*W*H)

Electric control system: PLC treadle control

Power voltage: 380V/50Hz/3PH

Motor power: 4KW (corner brace riveting) + 4KW (support bar riveting) + 4KW (Frame riveting) + 3KW (weatherstrip riveting), 15KW in total

(IV) Actual Product Photo:

VIII. Related Complementary Molds

1. One set of fire damper common-plate corner brace mold (with one separate pair for decoiling and forming respectively)

2. One set of leaflets fitting mold (with one pair for decoiling, and two pairs for forming)

3. One set of baffler notching mold

4. One set of connecting rod punching mold

5. One set of blade cover plate mold (with one separate pair for decoiling and forming respectively)

Fire damper other accessories

Fire Damper Blade Making Machine | Fire Damper Spring Leaf Making Machine | Fire Damper Support Bar Making Machine | Fire Damper Frame Making Machine |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★