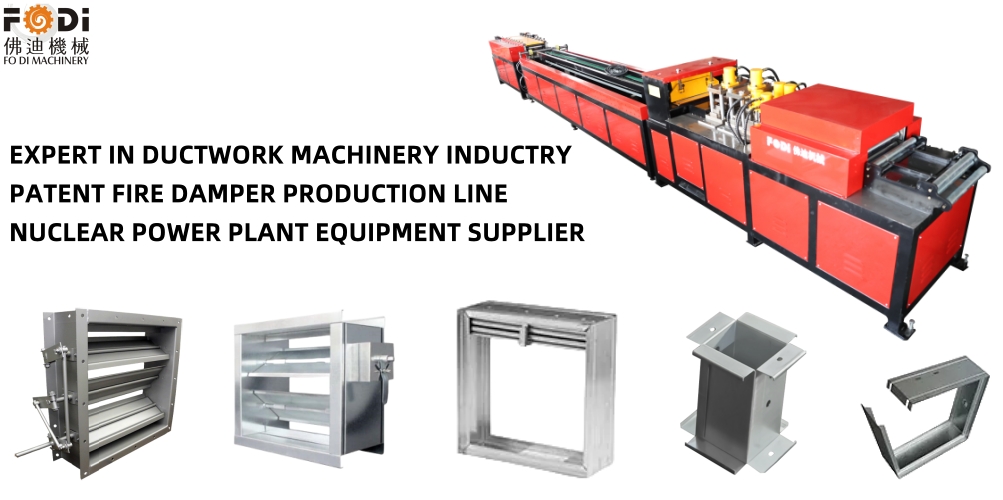

Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

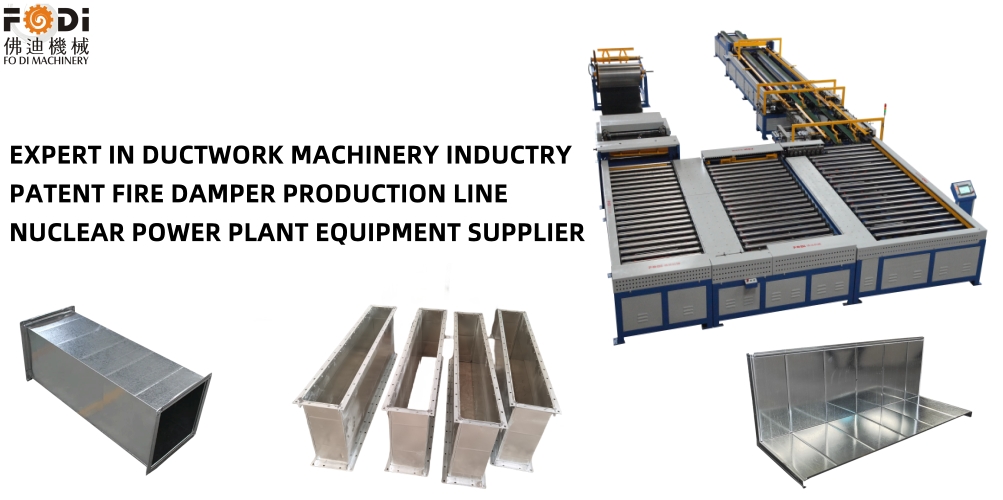

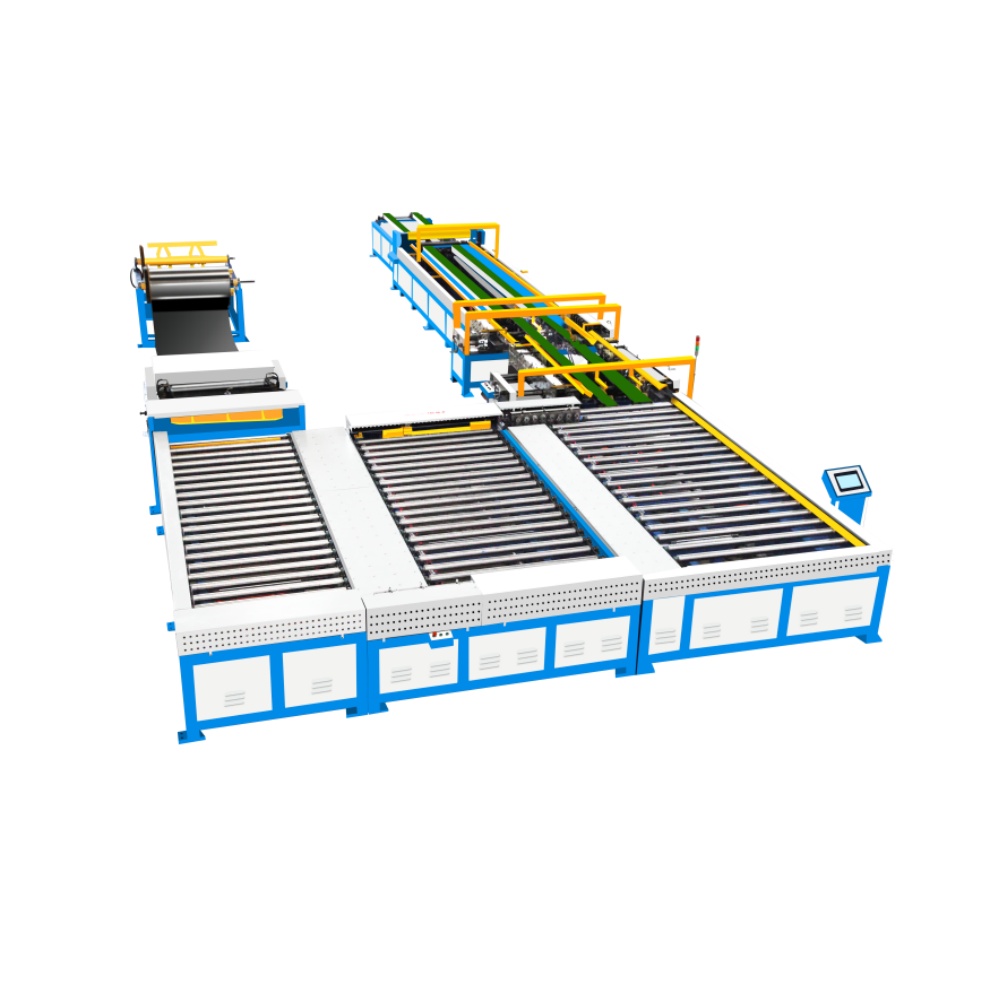

Air Duct Automatic Production Line VIII

3 different kinds of Flange forming functions are available(TDF/TDC/CS Insert Flange)

No need to change the roller gaps to meet the thickness of the material because we are using the dual lock forming machines.

Air Duct Automatic line VIII is u shaped distribution, small area, convenient installation, suitable for limited site manufacturers to use, fast, high efficiency.Average daily production duct is more than 2000 square meters. The production line has the automatic material-saving pattern, the processing plate has no scrap.

The Automatic CNC Duct Production Line VIII is our latest Duct coil line machine. With U-type structure, it reduces time of plate passing time which achieves the productivity of 18-25 seconds per piece. Pittsburgh Seam and Single Seam forming separately by Two Sets of Lock Forming Machine which makes the Pittsburgh Seam is processing in the front. When producing large-size duct, the short side bent first, which is more suitable for the Duct Seam Closing and Heavy Gauge Material.

Features:

★ During feeding mechanism with Hydraulic servo system, manipulator helps to ensure stability and speed of the machine, and the accuracy of its locating system.

★ It only takes 18-25 seconds to make one L-shaped workpiece and the efficiency will double compared with the linear type.

★ Daily processing capacity can reach 800-2500 suqare meters.

★ All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times.

★ Under the material-saving mode of CNC system, waste is less than 20 mm per roll.

★ With production memory functions, the production orders can be tracked and checked.

★ The short side is formed first, which is more suitable for Duct Seam Closing and Heavy Gauge Material.

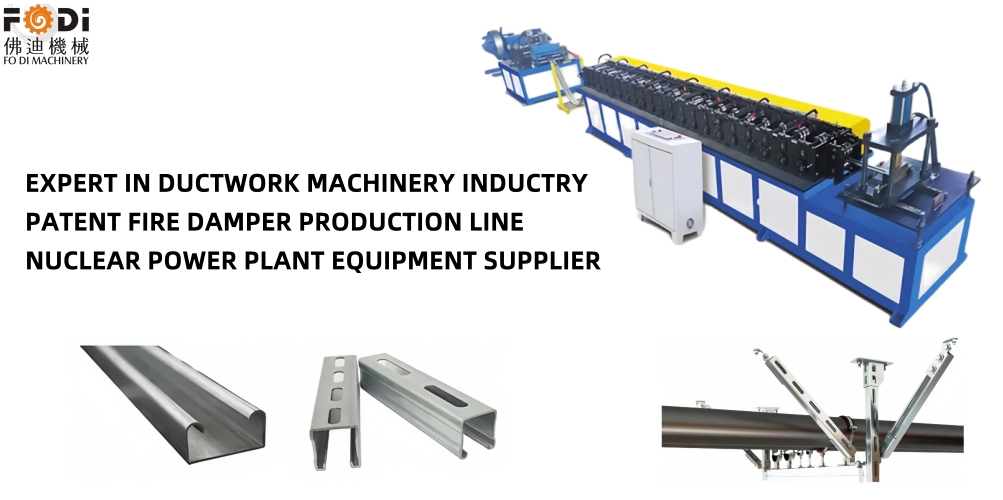

Other realted machines for air duct

Air Duct Corner Assemble Machine | Hydraulic Air Duct Seam Closer | Welding Machine for Angle Steel | TDF Folding Machine |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

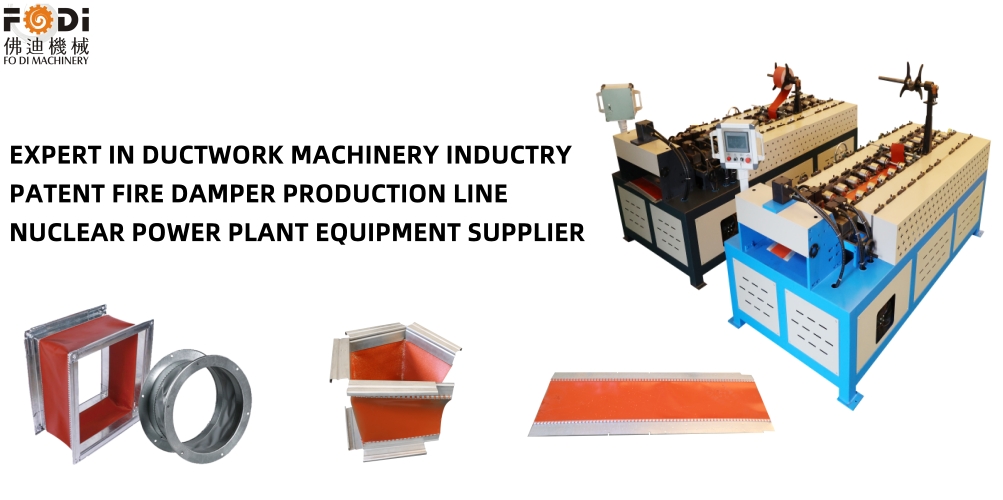

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|

|

|

|