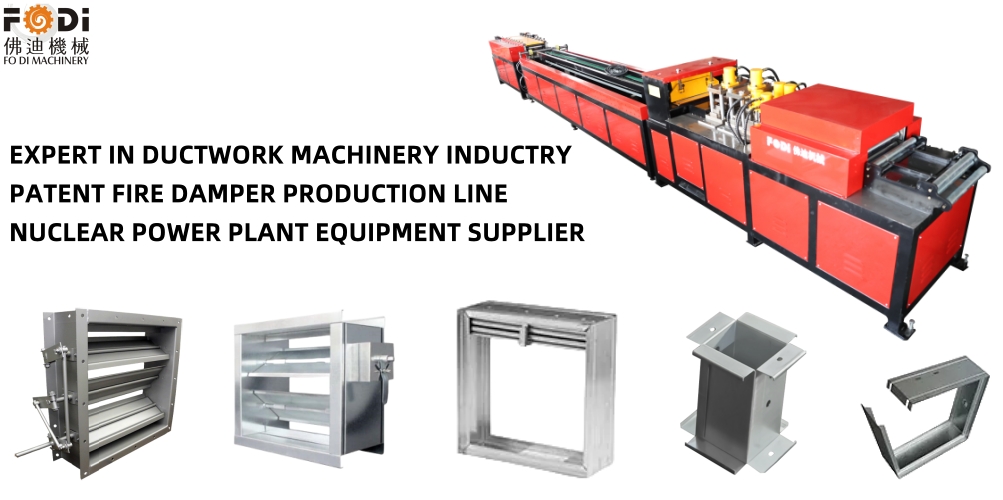

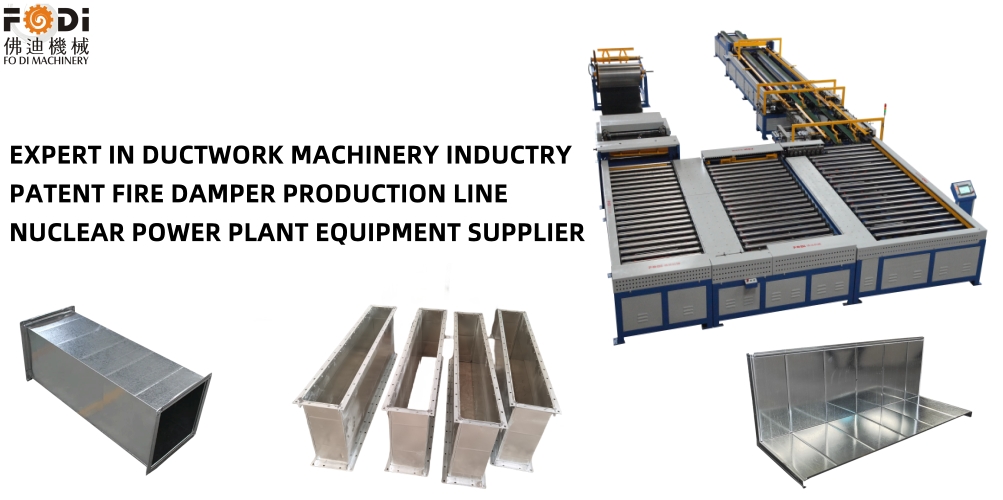

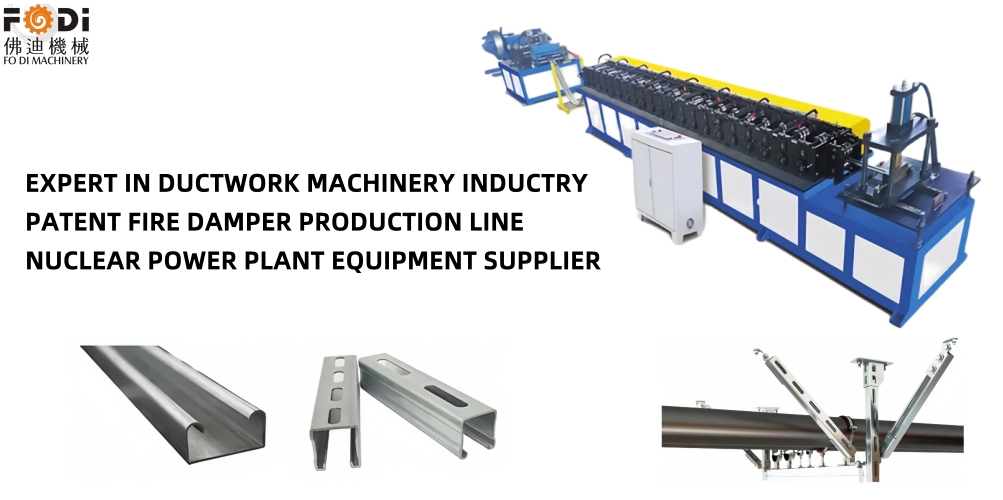

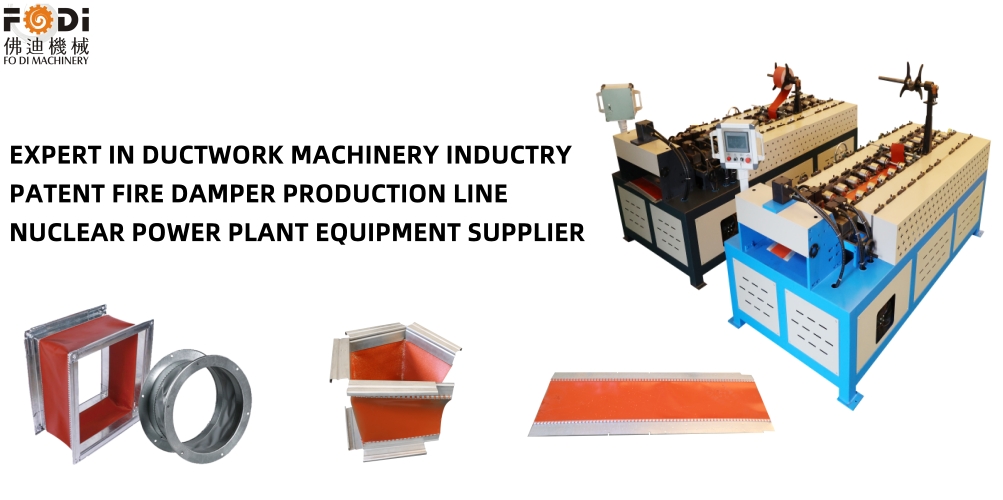

Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

Round Duct Elbow Making Machine

On a single machine platform, elbow making machine is efficient and costeffective solutions to the production of elbows, reducers, end caps, and offsets and provides you the ability to fabricate quality standing seam fittings in-house.

The dual workstations guarantees the maximum flexibility.lt eliminates the needs of frequent replacements.The nippping speed can reach 120m/minute reaching a high level performance.The processing width is 1.5mm for galvanized steel sheets and 1.0mm for stainless steel sheets.lt inproves the quality of the seam,so that it does not require any maintenance or lubrication.All roller accessories are madeof steels of high strength and quality.

It's also used for interface modeling and commissure of shrimp elbow tube, also elbow machine for spiral round duct is for producing round elbows in ventilation & air conditioning system. With the hydraulic power to ensure higher capacity for spiral round duct. Due to there`re two styles of elbow machine: electric and hydraulic, with two working location both, one is used to process single and double profile, and the other is used to connect and press. And our elbow machine can connect tubes by machine with perfect efficiency, good seal, and stability.It`s easy to operate and it can process tubes with a different diameter.It replaced the traditional handwork method totally.It suits such industries as ventilation, refrigeration, environment protection project. Each equipment in the round duct processing machinery is developed strictly according to the corresponding requirements from rolling, locking, seaming, leveling and beading, each round duct processing requires have a corresponding machine to maximize the efficiency of processing also reduces the cost of customer use and we have high-quality requirements for ourselves. All of our mechanical parts are using the highest quality brand suppliers toensure the stability and quality of our products. Round duct elbow machine is the only equipment that can connect the round duct and can adjust the wind tube bending direction arbitrarily, and the work diameter is 120mm~1000mm, although the machine is large, the motor power just 3kw, this means that the machine is very energy efficient, this is the biggest surprise for customers in need. We are relentless in pursuit of customer satisfaction commitment: 48 hours of service to users in place. Users think of things we have to think that customers do not want to do we do, users of the products, service quality, reputation, firm, this round duct elbow machine maximum thickness is 1.2mm, also the size of this machine is length: 2220mm, width: 920mm, height: 10500mm, but this machine weight is 450kg. So we added the pulley to the bottom, to make the machine easy to move.

Air Duct Corner Assemble Machine | Hydraulic Air Duct Seam Closer | Welding Machine for Angle Steel | TDF Folding Machine |

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

|

|

|

|