Foshan Nanhai Fodi MachineryAir duct fire damper calble tray automatic production line manufacturer |

|||||

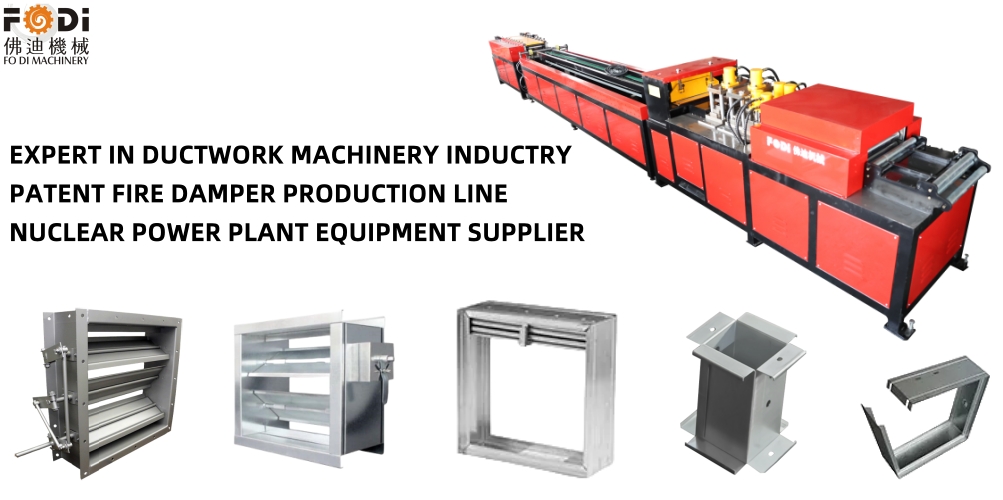

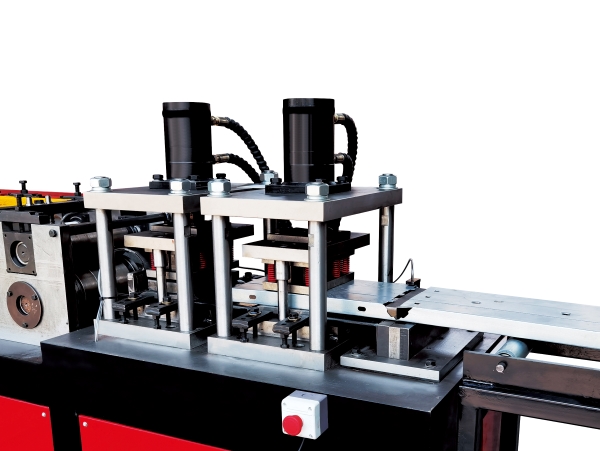

Fire damper Frame Automatic Production Line for HVAC/VCD-Buckle Type

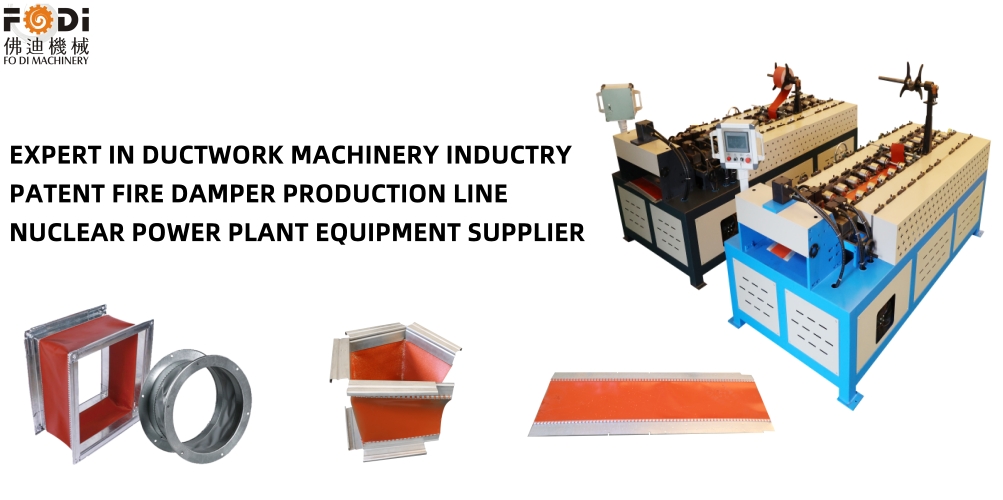

The fire damper series of equipment mainly consists of: (I) the Frame production line; (II) the blade forming machine; (III) the support bar forming machine; (IV) the leaf spring forming machine; (V) the positive pressure air supply outlet production line; (VI) the positive pressure air supply outlet baffler production line; (VII) the riveting platform; and (VIII) the related complementary molds.

Name, model, specification | Remark |

Buckle-Type Outer Frame Production Line for HAVC/VCD/Fire Damper (220mm) | 35mm common plate; 1.2~1.5mm galvanized sheet; punching Fuse hole and shaft holes; and cutting to length |

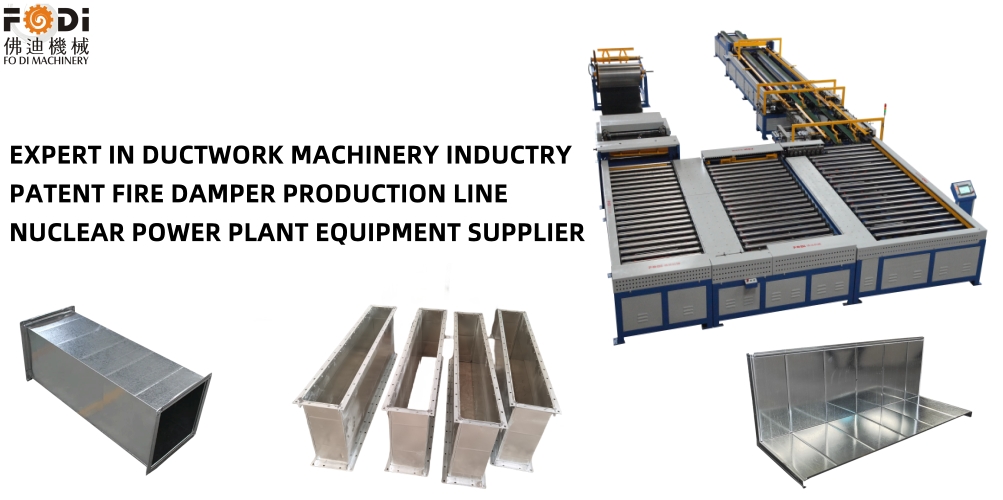

(II) Main Process Flows

The coil is placed on the feed rack and tensioned manually. It is leveled up through the leveling machine and fed to length over the feeding roller powered by the servo motor. It then goes through two pairs of profiling molds and hole molds, to form holes and shear angles for splicing. Then through the guiding board, it enters the forming machine and formed into common-plate flanges by 18 pairs of cold bending rollers. Thereafter, through two pairs of blanking molds and one pair of cutting molds, it turns into a valve body blank with four sides. The cut workpiece is manually folded into a frame and buckled up, to build a complete valve body.

Decoiling → Plate guiding → Leveling → Profiling molds (5 pairs) → Punching rotor shaft holes (16mm) → heat detector hole (20mm) → Cold bending → Profiling molds (for modification) → Cutting to length → Collection rack → Folding into frames manually

Fire damper other accessories

Fire Damper Blade Making Machine | Fire Damper Spring Leaf Making Machine | Fire Damper Support Bar Making Machine | Fire Damper Rivet Table |

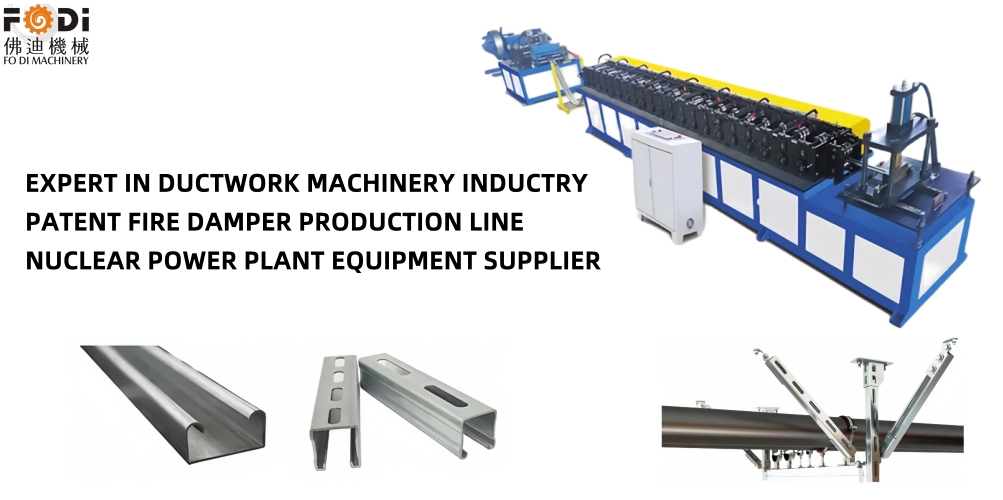

Fodi Machinery Co.Ltd Development History

★ Profound experience in HVAC Ducting Machinery (Since 1988).

★ Profound experience in Automatic Spiral Duct Forming (Since 2004).

★ Profound experience in Automatic Duct Production Line (Since 2006).

★ Have the largest inventory for HVAC Duct Making machines in the industry.

★Got Pantened for Fire Damper Series

★ Real manufacturer with the most complete varieties of HVAC Ducting Machinery in China.

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★

Air Duct Working Site | Fire Damper Working Site | Air Duct Need Machine Working Site | Angle Steel Machine Working Site |

★★★Fodi company can give you both CNC duct production line machine which can manufacture air duct automatically. We will suggest a whole machines series in accordance with different customers needs★★★